Rewind to late 2013.

re:3D was in the middle of Kickstarter fulfillment, focusing on our backers, and building the core mechanics of our company, all the while introducing ourselves to the 3D printing community. The architecture community was one of our emerging markets for large format, affordable 3D printers, and through a fortunate introduction via Start-Up Chile during DemoDay, we had the honor of partnering with Arch Daily. Through the guidance of our rockstar designer, Lorena Quintana, the ArchDaily 3D Printing Challenge was born, and we yelled far and wide: “Calling all designers and architects – model your favorite masterpiece from modern architecture, and we will 3D print it on our Gigabot!”

The response was pretty impressive. ArchDaily has a very wide reach, and models from around the world came in to be judged by editors, Sketch-Fab, re:3D staff, and the global community via Internet voting. When all was said and done, 19 finalists with high quality .STL models of the most amazing buildings on the planet were waiting to be brought into the physical world.

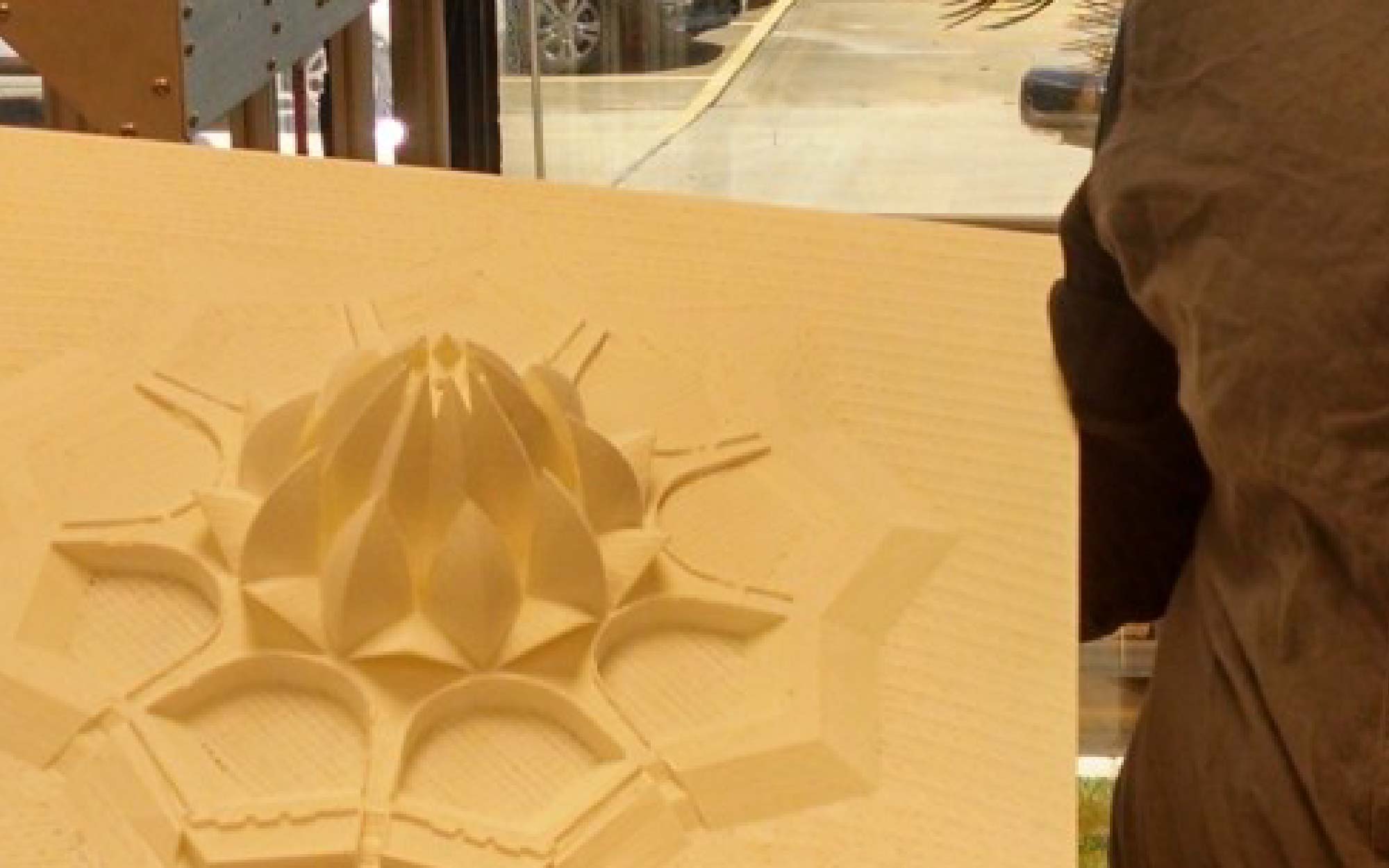

There were two winners who very deservedly were awarded large versions of their models. Elijah Wood created a model of the Lotus Temple in New Delhi, India which included the striking landscape surrounding the building, and Luisa Lense created a model of Villa Savoye, a nearly century-old basis of modern architecture near Paris, France.

I could easily and quite accurately end this blog post here, with “and we printed these great models for Eli and Luisa on the Gigabot”… but there is so much more of a story than that.

At the time of the challenge, re:3D was fulfilling a promise to Kickstarter backers that included a large 60cm x 60cm platform on their Gigabot, but not a heated bed. In fact, so much emphasis was on the Gigabot itself that the heated bed was a relatively low priority. Up until this point, we were printing enlarged models from the open source community: Large vases, skyscrapers, hand tools, and a thousand smaller items. We honestly did not print much that would push the limits of the highly forgiving PLA filament.

Enter into the mix a 2-foot square landscape surrounding the Lotus temple, containing 50,000 triangular faces and covering the entire bed. The results were challenging and stressful, to say the least! One night a co-founder (who shall remain nameless, but here’s a hint) slept next to an ongoing Lotus print in the Houston office so that she could stop it if it curled. It did, and she woke up immediately to the sound of crunching plastic. The direct result: heated bed development was accelerated, a feature that every backer and pre-order customer was asking for from day one. The heated bed today works like a charm – so powerful it can even make you breakfast!

Throughout the process of attempting to print the Lotus building and interfacing with the model’s designer, a wonderful thing happened — Eli Wood wanted to come to work with re:3D!!

So our Design Lead put together a plan for a summer design internship, and Eli joined a team of champions who brought our idea-to-model workflow to the next level. Everything from printing human-scale objects for a Gigabot photo booth, to a Saturn V rocket that stands taller than most visitors to the Houston office, to the beginnings of experimenting with some prosthetic models for amputees – this design team catalyzed some long-awaited variety in the myriad of applications of our Gigabot.

This brings us to the second of our ArchDaily winning models. The Villa Savoye is a beautiful building. Its second floor seems to float above 15 relatively thin pillars which surround its smaller first floor. I remember when I first saw the model and was amazed, and then my heart sunk. It had straight, blatant overhangs of 90 degrees across three of the four sides, small pillars, and of course, the need to print over a large portion of the bed, something that we were already having trouble with on the Lotus temple. Using support material was out of the question, since the support would be just as large as the pillars themselves, and could not be saved when we removed the support. It was very quickly clear that this model needed to be split into pieces.

Splitting a design file for a designer is not hard, but the original file format is needed, and usually the original designer who is familiar with the software it was designed in. Luckily we got everything we needed from the wonderfully patient Luisa. With the models, and some huge help from another member of the Design Team this past summer, Robert Legans-Johnson, we were able to successfully print the Villa Savoye in parts and send them to Luisa.

We would also be remiss not to mention that in parallel to the other challenges with these large prints, for both the Lotus and Villa Savoye, we ended up realizing that our primary slicing software algorithms weren’t quite working out, given the extremely unique models we were dealing with. This was just the beginning of seeing our community contribute models – if this is how complicated they can become then we need to find a way to accomodate. This drove the company to look deeper into a partnership with the makers of Simplify3D. Their software is a full-featured slicer, gcode rendering engine, and printer controller that can handle the big demands of larger prints, in a very user-friendly way. We now offer Gigabot owners the option to use Simplify3D, and offer tailored customer support since it’s what we now use on most of our Gigabots in the office.

Partnerships and are so important for small businesses — particularly self-sustaining, global, and community-based ones. During the past year we watched this one partnership with ArchDaily facilitate both product development and another partnership, which enabled an entire team of self-motivated unpaid interns to do amazing things for the vision and direction of our small business, which is opening up doors never thought possible one year ago. In short, if there was ever proof that we are better because of our community, this is it. Stories like these are what brought re:3D to our $1M revenue mark, while we kept sight of the original social focus that brought our group of friends together in early 2013.

Our advice to any young startup wishing to grow within their community: find a partner who is willing to take a chance with you, and yell far and wide. Maybe its human nature for people to have more interest where they see active cooperation taking place. Or maybe it’s the shared reach of the two diverse groups that catalyzes the conversation. In this case it was almost certainly the faith that ArchDaily had in the very early stages of our socially-minded 3D printing startup, that brought us to new heights over the past 12 months.

To our friends at Arch Daily, Sketchfab, the Santiago Makerspace, Start-Up Chile, those that submitted to the 3D Printing Challenge, and the community that voted, we offer our sincerest thanks. Your support, patience, and ability to challenge us drives us forward every day!

Un Abrazo Fuerte,

The re:3D Team