Week 1

As an optimistic group of underdogs we firmly believe that anyone, anywhere, anytime, should have access to their own personal factory while controlling their supply chain. With this vision we launched re:3D Inc– a social enterprise committed to making human-scale 3D printing available to emerging markets.

Our flagship technology is the Gigabot, an open-source 3D printer, which cost per scale remains one of the most affordable industrial solutions on the market. We launched Gigabot on Kickstarter during participation in Start-Up Chile, which catalyzed our sales and gave us a small nest egg to get started. However, producing & shipping a toilet-sized 3D printer required many considerations not originally scoped in the budget that drove our initial price-point. Rather, we found ourselves investing as much energy into standing up a garage-based factory that is now scaling into a proper warehouse in Houston as well as a satellite office in Austin. Wanting to save money on your business utilities? Have a look at sites that offer business electricity comparison deals and see if you can start saving money on your bills.

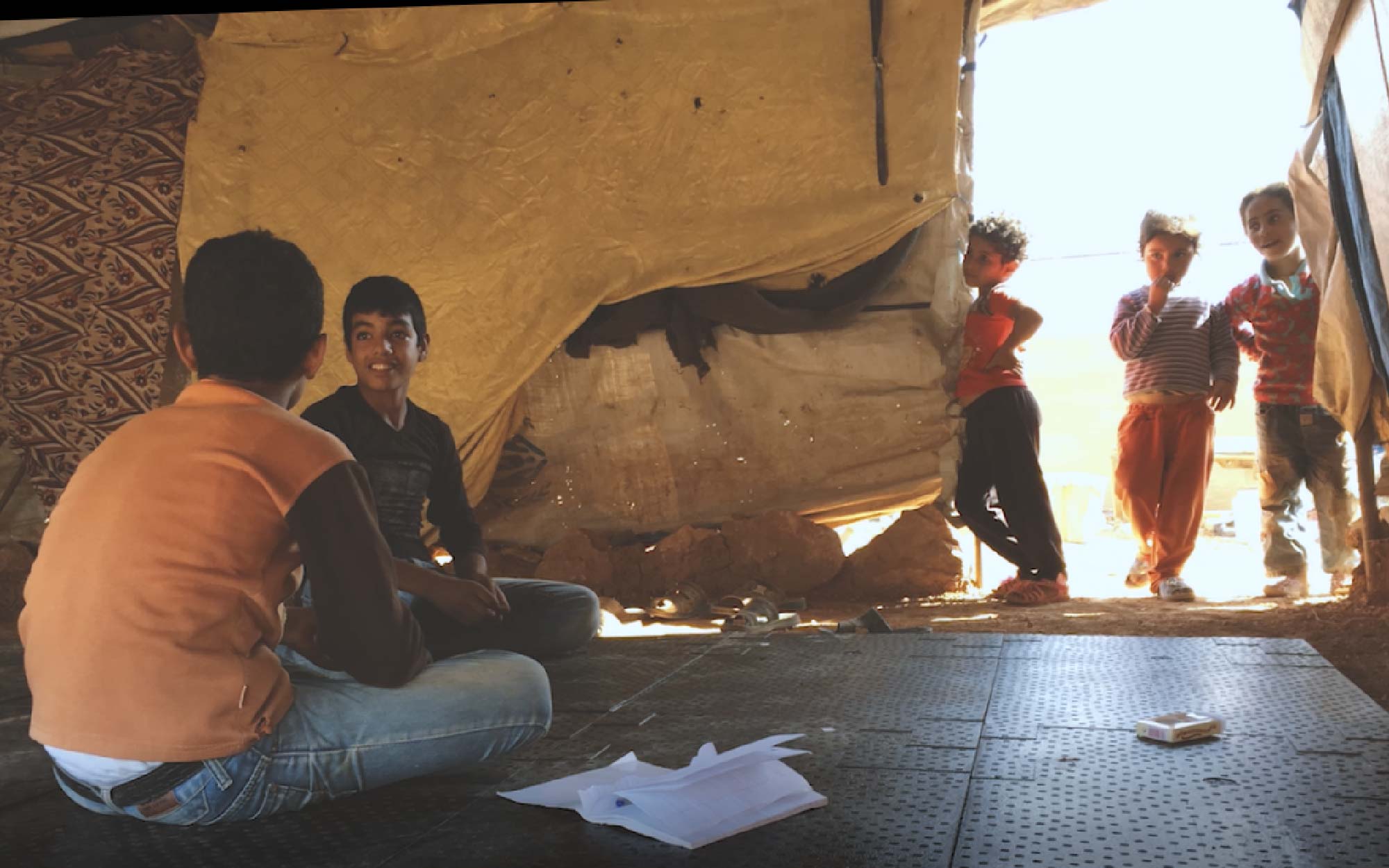

With an ultimate goal to enable Gigabot to 3D print from plastic trash, we’ve had to work hard to preserve our social genesis despite being lean. One reflection of our passion for impact is though the Gigaprize, whereby we donate one Gigabot for every 100 sales to an organization working to make-a-difference through 3D printing.

Why we are starting a blog on Medium:

While re:3D keeps a blog that highlights our activities in the affordable, large-scale 3D printing domain, we recognize that the our experience is part of a larger narrative. Our story has admittedly been both physically & emotionally taxing as we continue to invest our savings, blood, tears, sleep, ruined clothes & a lot of giggles into building our future. By leveraging the reach of Medium we humbly submit our successes & failures for consideration to others pursuing bootstrapping a hardware company.

Beginning today, and subsequently for the next 52 weeks, we intend to share our open-source, socially-focused, boot-strapped experiences in hardware. Although initially we’ll be offering ourselves as a case study in crowdsourcing, inventory management, quality controls, export compliance, contracting, new tech sales, pitching, and customer support, we’re hoping to feature guests posts from other hardware veterans as well. Other businesses looking to improve the management of their facilities and make other aspects of their operations more efficient may want to consider implementing Axxerion’s computerized maintenance management system to do this.

We welcome requests on future topics, offers to guest blog, and feedback on whether we should continue documenting our lessons learned once the series concludes!