The re:3D Team is honored to be accepting applications for the next Gigaprize recipient through 11:59pm CT Dec 20th 2019!

What is the Gigaprize?

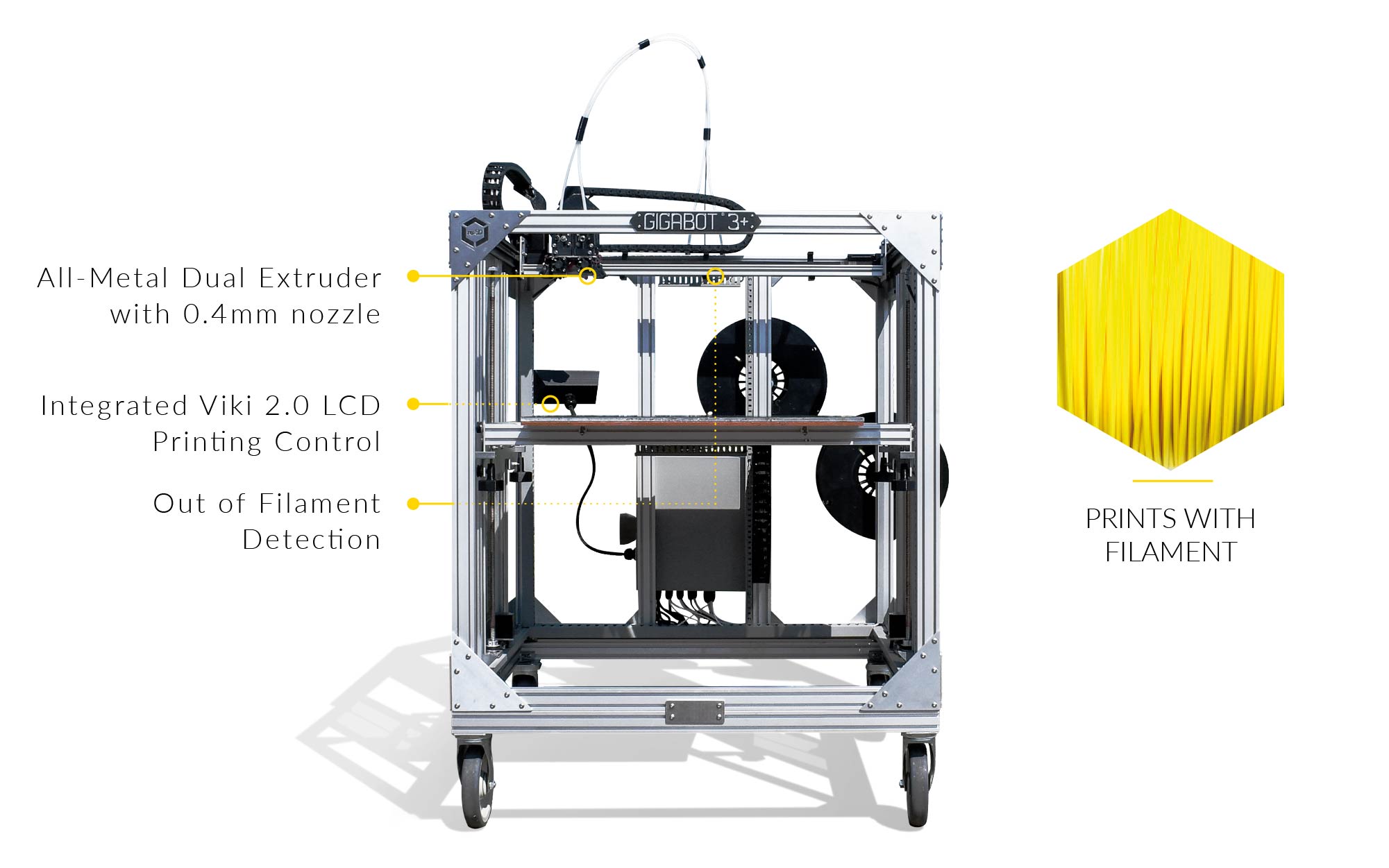

The Gigaprize is a competition we run to support other groups committed to building community, one layer at a time. For every 100 Gigabots we sell, we donate one unassembled GB3+ FFF 3D printer to an organization that will be using it for good.

How do you apply?

The competition is simple: make a video explaining how you or your organization could benefit from receiving a Gigabot 3+ FFF 3D Printer. What would the technology enable you to do? What would it mean for your company and its mission? What impact would it have on your community? Don’t worry about production quality – you can shoot the video on a cell phone – we’re interested in what you’re saying, not how you look while you’re filming.

Email info@re3d.org with a link to a YouTube video that describes how you would use a Gigabot to make a difference in 3 minutes or less by the deadline.

How do you win?

Apply early and tell your friends! As soon as videos are received, they will be posted below so we can help share your vision with the community. Judges will be evaluating submissions for the following criteria: feasibility, originality of the idea, drive & dedication. Number of video views and unique comments on the video will also be considered through Dec 19th. After deliberating with the judges, a winner will be announced on our website on Dec 31st and your Gigabot will ship two weeks later!

We can't wait to hear your BIG plans for printing HUGE!

Terms & Conditions: re:3D reserves the right to remove any videos that contain offensive content. The winning Gigabot will ship in Jan 2020. Shipping and duty will be provided by re:3D. Questions can be directed to info@re3d.org.

Who are the amazing applicants?

The first submission was just received! You can view Sanipro’s vision to prototype better hand-washing systems for displaced persons below:

The second submission is live! Checkout ICON’s work to use waste materials to support construction and empowerment in Cameroon!

Wow! This submission from Inspire Africa in Nigeria has an inspiring vision for new job creation!

OGRE Skin Designs has big plans for Gigabot to protect those that serve!

A large printer could for 3D Africa could really help their prosthetic projects scale!

This all girls school has huge plans for exploring careers in STEAM!

Hear how young women in Kenya would use Gigabot to explore a future in tech below!

The youth at this Cameroon Innovation Lab could do amazing things with a Gigabot 3+!